The American Coatings Show is the leading North American coatings industry event, setting trends for future developments in the industry. Attending the show facilitates immediate business opportunities, access to a complete portfolio of high-grade competitive products, and myriad networking and connection opportunities.

Join us at the American Coatings Show 2024 in Indianapolis, Indiana, USA, from Tuesday, April 30 to Thursday, May 02, 2024.

This year, Arkema is proud to unveil our most recent innovations contributing to more sustainable solutions, further decarbonization, and more circularity across the industry !

Our Groups will leverage our pioneering specialty resins and additives offering and expertise in the lowest Volatile Organic Compound technologies to build solutions-oriented answers addressing sustainability, high performance, and anticipation on regulatory evolutions.

Make your coatings, inks and adhesives more sustainable!

Arkema's portfolio of materials for coatings offers manufacturers a wide range of ingredients. Our materials and formulation expertise supports the development and production of durable, high-performance paints, coatings and inks that meet the latest and most stringent regulations.

Access our range of materials for coatings here!

Key sustainable answers

Decarbonizing the built environment: contribute toward building a more resilient environment by using materials with lower embodied carbon and longer lasting performance.

Enhancing new mobility efficiency: Optimize performance and improve battery energy density, duration, weight reduction and recharge time.

Enabling more circular housing: Design more circular and bio-based products with matching performances to offer premium alternative to end-consumers.

Reducing energy consumption of buildings: Improve indoor thermal comfort and reduce air conditioning consumption by installing cool roof coatings to reflect the sun.

Supporting community health and well-being: Build trust with consumers and address their heigtened safety concerns by using the right materials.

American Coatings Show 2024 Conferences + Product Presentations

Flagship Coating Solutions to Advance Sustainability

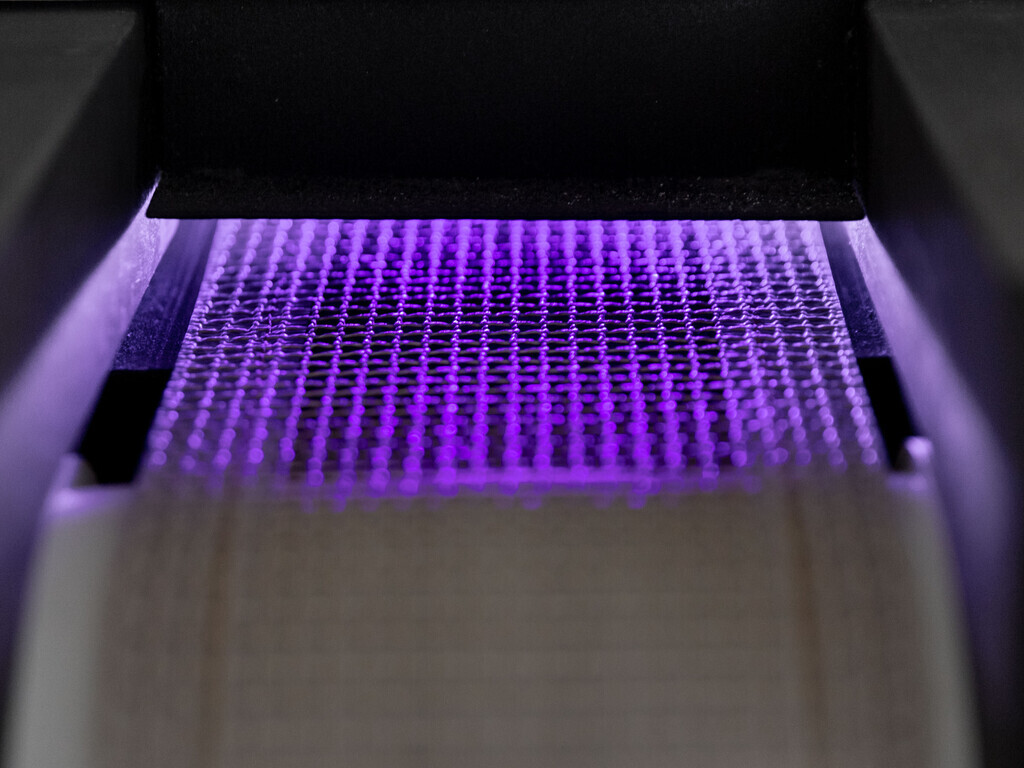

Low-VOC, solvent-free resin development for UV/EB cured coil coatings

Enhancing Your Building’s Sustainability Profile with Long Life Coatings

Advances in 1K PVDF/acrylic hybrid dispersion and its applications

Mass Balance Solutions to Accelerate the Shift Towards More Circular Solutions

The Path Forward to Safer 2K Paints

Improving the sustainability of high-performance water-based DTM coatings

Building performance exterior acrylics to master regulatory challenges

Energy-curable solutions for low-VC, dielectric EV battery coatings

New Pure Associative & Newtonian HEUR Polyurethane Thickener for Water-Based Systems

Practical information

- When ?

From April 30 to March 02, 2024

- Where ?

INDIANA Convention Center

100 S. Capitol Ave.

Indianapolis, IN 46225

United States- Booth ?

Booth #1130

.png)